Professional Windows and Doors Customization Manufacturer

Wellcome To ROPO Windows and Doors Factory

Accuracy Is KeyIn the making of windows and doors, there is no one-size-fits-all. The ROPO production team pays attention to the dimensions, angles and everything that might affect accuracy.

The Pursuit of PerfectionEven the seem-easy handiwork are seriously considered. From removing stains on the frames and glass, to assembling windows and doors, our workers are always in pursuit of perfection.

Functionality AssuredEach window and door is tested with our wall simulator, making sure each works as expected.

Packaging MattersROPO invests in packaging utilizing 5 layers of protection because poor packaging might result in distortion of the frames and cracks in the glass.

- Incoming Inspection Specification

- In-process Inspection

- Final Products Inspection

Incoming Inspection Specification

| Serial Number | Raw and Auxiliary Materials | Inspection and Recording Items | Frequency | Testing Method | Record Form |

|---|---|---|---|---|---|

| 1 | Glazing | 1.Meet AS/NZS 2208, AS4666, IGCC requirements 2.Check the outgoing inspection report provided by supplier 3.Check product specification, size, thickness, certificate and batch information. 4.Dimension check of thickness, width and height of glazing. 5.Appearance check, no scratches, bubbles, sand marks.. | 3 pcs/batch | Visual check Devices | IQC inspection report |

| 2 | Aluminum Profile | 1.Check the batch, quantity, specification and dimension 2.Check the supplier’s certificate of conformity 3.Check the appearance of coating 4.Thickness of coating check: average thickness is min. 60um, area thickness is min. 48um. Adhesion test: level 0 5.Length of the profile, wall thickness check to meet drawing 6.Appearance check | 5 pcs/batch | Visual Devices | IQC inspection report |

| 3 | uPVC Profile | 1.Check the appearance, dimension and thickness of UPVC 2.Check the testing report of certificate of conformity each year. | 3 pcs/batch | Vernier caliper | IQC inspection report |

| 4 | Critical Hardware | 1.Check the batch, quantity, specification and packaging 2.Manual operation or assembly in the product to check whether it is ok or not ok. | 3 set/batch | Visual Test equipment | IQC inspection report |

| 5 | Sealants or Silicone | Check the batch ID, quantity, specification and packaging | 1 pc/batch | Visual | IQC inspection report |

| 6 | Other Small Hardwares | 1.Check the batch, quantity, specification and packaging 2.Dimension check (if applicable) appearance and color. | 5 pcs/batch | Visual Devices | IQC inspection report |

| 7 | Gasket | 1.Check the batch ID, quantity, specification and packaging 2.Pre-assembly in the product. | 10 sets/batch | Visual Assembly | IQC inspection report |

In-Process Inspection

Cutting

PassedWork focus: Cut the corresponding raw materials according to the "Production Bill of Materials"

- Operation reference file:

Milling

Work focus: 1.Mill out the corresponding sink holes and lock holes according to the "Production Bill of Materials"2. Threaded mullion, face milling and V opening.3. Cut the steel lining and fasten the steel lining.

- Operation reference file:

Welding

PassedWork focus: Weld the corresponding products according to the "Production Bill of Materials"

- Operation reference file:

"Frame Welding Operation Instructions" (LB-WI-SC-05, LB-WI-SC-06)

Clean corner

Work focus: CNC machine cleans the welding slag at each corner of the product

- Operation reference file:

Surface

PassedWork focus: 1. Install the adhesive strip according to the "Production Bill of Materials" 2. Check the appearance and clean it, and put on a new protective film

- Operation reference file:

Installation

PassedWork focus: Install the corresponding hardware according to the "Production Bill of Materials"

- Operation reference file:

"Hardware Assembly Operation Instructions" (LB-WI-SC-35 to LB-WI-SC-40)

Installation Glass

PassedWork focus: Cut the glass bead according to the "Production Material List" 2. Install the glass according to the "Production Material List"

- Operation reference file:

FQC

PassedWork focus: Check according to the customer's drawings and record it in the "FQC Inspection Record Form"

- Operation reference file:

Packaging

Work focus: Packaging according to the "Production Bill of Materials"

- Operation reference file:

Cutting

PassedWork focus: Cut the corresponding raw materials according to the "Production Bill of Materials"

- Operation reference file:

Milling

PassedWork focus: Milling out the corresponding keyholes and sinks according to the "Production Bill of Materials"

- Operation reference file:

"Hole Milling Operation Instructions" LB-WI-SC-55, LB-WI-SC-56

Surface

PassedWork focus: Install tops and rubber strips according to the "Production Bill of Materials" and check the surface quality of raw materials

- Operation reference file:

Frame Assembling

PassedWork focus: Milling out the corresponding keyholes and sinks according to the "Production Bill of Materials"

- Operation reference file:

Surface

PassedWork focus: 1. Install the adhesive strip according to the "Production Bill of Materials" 2. Check the appearance and clean it, and put on a new protective film

- Operation reference file:

Installation Hardware

PassedWork focus: Assemble the hardware according to the "Production Bill of Materials"

- Operation reference file:

Installation Glass

PassedWork focus: Cut the glass bead according to the "Production Material List" 2. Install the glass according to the "Production Material List"

- Operation reference file:

Adjusting

PassedWork focus: Debug five corresponding doors and windows according to the "Production Bill of Materials"

- Operation reference file:

"Window and Door Adjusting Operation Instructions" LB-WI-SC-60

FQC

PassedWork focus: Check according to the customer's drawings and record it in the "FQC Inspection Record Form"

- Operation reference file:

Packaging

Work focus: Check the glass and appearance according to the "Production Bill of Materials" and pack it according to the customer's requirements

- Operation reference file:

Final Products Inspection

| No. | Procedure | Operator | Control Points | Frequency | Tools | Records |

|---|---|---|---|---|---|---|

| 1 | 100% check | QC | Dimension check: the tolerance of width and height is ±3.0mmTolerance of squareness is 4mm | 100% | Tape | LB-FR-SC-07 FQC report |

| 2 | 100% check | QC | Functional and assembly quality check: Manual operation of the products to check the basic function and accessories. Visual and tools to check the assembly quality, such as gap between the frames or between glazing and frame. | 100% | Visual Manual operation | LB-FR-SC-07 FQC report |

| 3 | 100% check | QC | Appearance check Of coating: by visual Coating meets requirements of AS3715. | 100% | Visual Manual operation | LB-FR-SC-07 FQC report |

| 4 | 100% check | QC | Operating force test: AS2047:Testing method is AS/NZS4420.1:2016 (Each sash shall be tested three times for both opening and closing, take the average value as the Max. initiate and maintenance force). NZS4211:Testing method is AS4420.3:1996, the maximum value shall not exceed the following values listed in table 2. | 100% | Pull-push gauge | LB-FR-SC-07 FQC report |

| 5 | 100% check (only for NZS4211) | QC | Friction resistance test: 35 time the sash area (in m2) force applied to the edge furthermost from the hinge or pivots, the sash shall not move.This force shall be applied at all angles of opening up to 70% of the maximum opening distance. | 100% | Visual | LB-FR-SC-07 FQC report |

| 6 | 100% check | QC | Label check: to check the label meeting production order | 100% | Visual | LB-FR-SC-07 FQC report |

| 7 | 100% check | QC | Appearance check:no marks, blurs, dent marks or glue. No color difference, scratches and other defects. | 100% | Visual | LB-FR-SC-07 FQC report |

- Q: Where is your factory?A: We are in Fuzhou City, Fujian Province, China

- Q: How many windows do you make one month?A: 5000 Square Meters per month

- Q: how many years is your factoryA: 16 years

- Q: can we visit your factory?A: Yes, welcome you to visit our factory

- Q: How many people is in your factory?A: 40 Workers, 8 Engineers, 2 QC, 6 professional consultants

- Quick selection quotation

- Become ROPO Windows Partner

- Australia Homeowner Quotation

- *Name

- *Tel

- *Name

- *Tel

- *Name

- *Tel

Partnership

- Custom UPVC Windows

- uPVC Casement Windows

- uPVC Sliding Windows

- uPVC Awning Windows

- uPVC Tilt & Turn Windows

- uPVC Fixed Windows

- uPVC Folding Windows

- uPVC Tilt Windows

- uPVC Hand Crank Windows

- uPVC Bay & Bow Windows

- UPVC Single Hung Windows

- UPVC Double Hung Windows

- uPVC Combination Windows

- uPVC Sound-Proof Windows

- uPVC Hurricane Impact Windows

- UPVC Passive House Windows

- Custom Aluminum Windows

- Aluminum Casement Windows

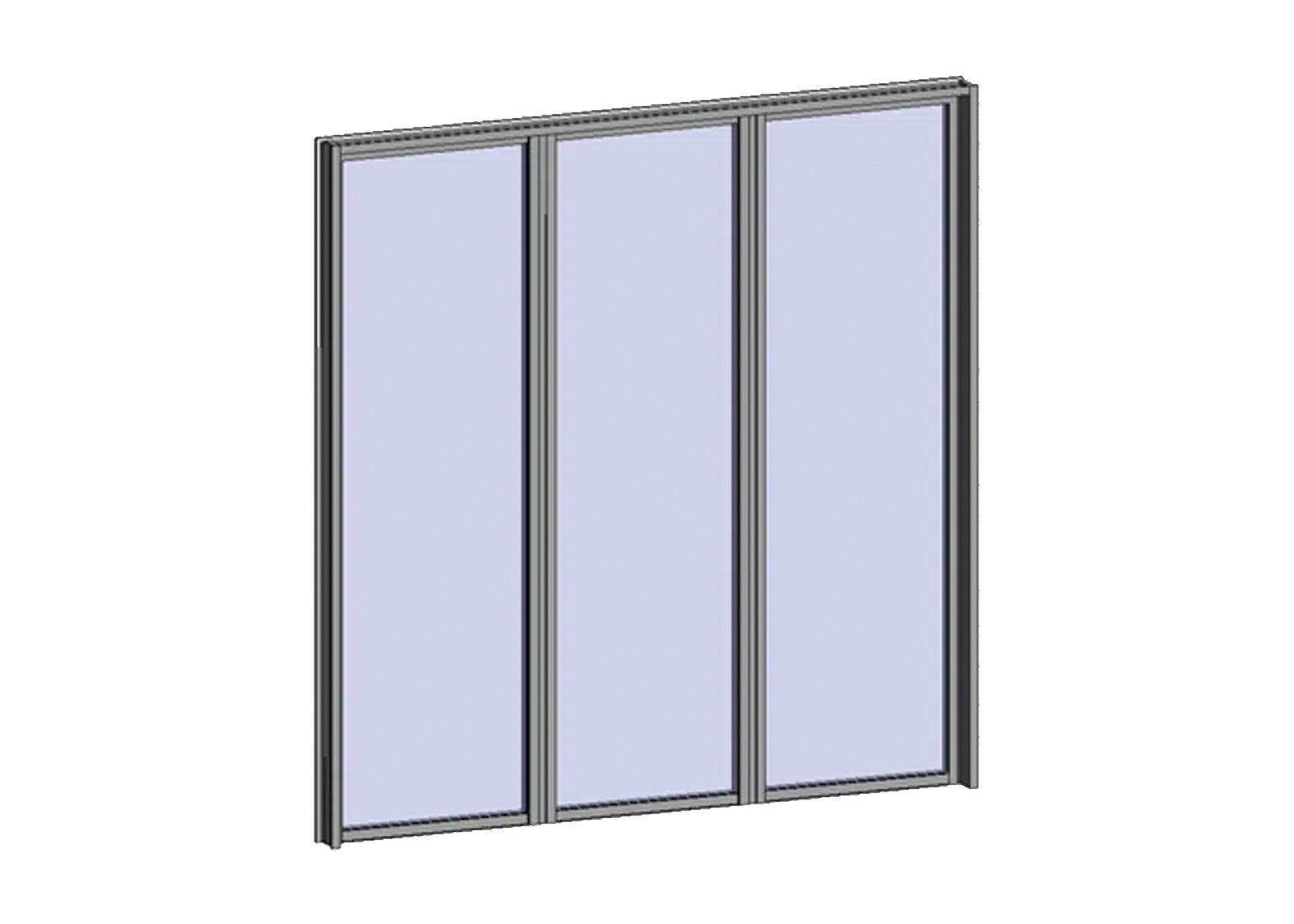

- Aluminum Sliding Windows

- Aluminum Awning Windows

- Aluminum Tilt & Turn Windows

- Aluminum Fixed Windows

- Aluminum Folding Windows

- Aluminum Tilt Windows

- Aluminum Hand Crank Windows

- Aluminum Bay & Bow Windows

- Aluminum Single Hung Windows

- Aluminum Double Hung Windows

- Aluminum Combination Windows

- Aluminum Fold UP Windows

- Aluminum Hurricane Impact Windows

- Australian Chain Winder Awning Windows

- Aluminum Gas Strut Windows

- Aluminum Parallel Opening Windows

- Aluminum Louver Windows

- Custom Timber Windows

- Custom Aluminium Wood Windows

- Custom UPVC Doors

- Custom Aluminum Doors

- Custom Timber Doors

- Custom Aluminium Wood Doors

- Custom Garage Doors

- Custom Interior Doors

- Custom Glass Railings

- Custom Shower Screen

- Custom Hurricane Shutters

- Sunshade Series

- Name:

- Benson

- Tel:

86-591-87147106

- Email:

- sales@ropowindows.com

- WhatsApp:

- https://wa.me/8615980112550

- Address:

- Address: No. 1 Phase, Tieling Technical And Economic Development Zone, Minhou County, Fuzhou City, Fujian Province, China